Multi-Standard System Enhances Mining Port Efficiency

Today, Hebei Juntong Machinery Manufacturing Co., Ltd. officially launched the "MRT Pro" series intelligent belt conveyor system, which integrates dynamic self correction technology, permanent magnet direct drive energy-saving module, and AIoT remote operation and maintenance platform. It can adapt to high impact mining conditions of tens of thousands of tons and 24-hour continuous operation scenarios in ports, saving 30% energy and reducing maintenance costs by 45% compared to traditional equipment.

Core innovation breakthrough

The system adopts a modular architecture and utilizes the patented technology of "standard cartridge" to achieve rapid replacement of the four key components of CEMA/DIN/JIS/GB standards, meeting the unified management requirements of cross-border project equipment. At present, this technology has passed the German T Ü V safety certification and the EU CE Machinery Directive.The "Junlian Cloud Control" platform is equipped with real-time monitoring of over 500 parameters such as conveyor roller temperature rise, conveyor belt tearing, and conveyor pulley bearing vibration, with a warning accuracy rate of 98%. This technology originated from the cooperation with China University of Mining and Technology, and successfully avoided three belt breakage accidents in a copper mine project in Chile, recovering more than 20 million yuan in losses for customers.

Full chain ecological compatibility

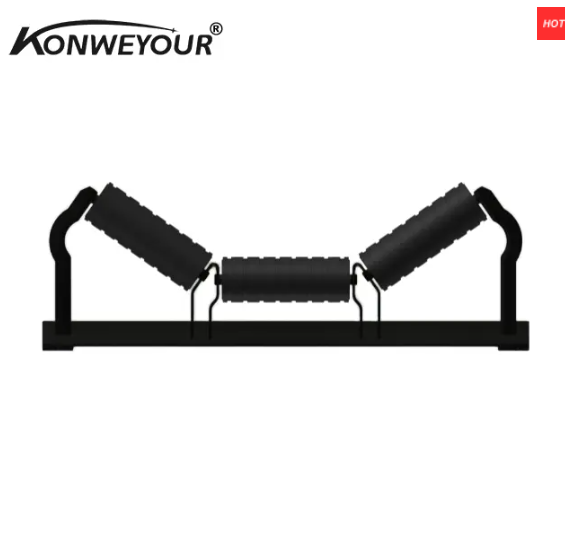

The product covers the entire machine with a bandwidth of 500-2400mm, as well as core spare parts such as wear-resistant conveyor rollers, ceramic coated rollers, and polyurethane cleaners. The impact resistance of the impact bed has been certified by SGS laboratory with a lifespan of 2 million cycles and is suitable for extreme environments ranging from -40 ℃ to 120 ℃.

Market validation

The first batch of equipment will be applied to the Indonesian nickel ore transportation project, achieving a 98.7% operational availability in an 8 ° slope and 15km long-distance transportation. At the delivery ceremony, General Manager Li Shuo said, "What we provide to our customers in 40 countries around the world is not just equipment, but an ecological solution for material transportation based on a multi standard system – from Brazilian iron ore to Russian permafrost, Juntong makes complex working conditions simple and reliableThis series of products has been selected as one of the top 100 demonstration cases for intelligent manufacturing in China in 2025. Starting today, the "Efficiency Doubling Plan" will be launched globally, providing free energy audit and upgrade solutions for ordering enterprises.