Belt conveyors and roller conveyors are two common types of material handling equipment used across industries such as manufacturing, warehousing, logistics, and packaging. Although both are designed to transport goods efficiently, they differ significantly in their structure, operation, and ideal applications.

A Belt Conveyor uses a continuous looped belt made of rubber, fabric, or synthetic materials to move products from one point to another. The belt is supported by rollers or a flat surface and is driven by pulleys connected to a motor. Belt conveyors are ideal for transporting a wide range of items, including bulk materials, small parts, and packaged goods. They offer smooth and consistent movement and can handle inclined or declined paths, making them suitable for diverse applications.

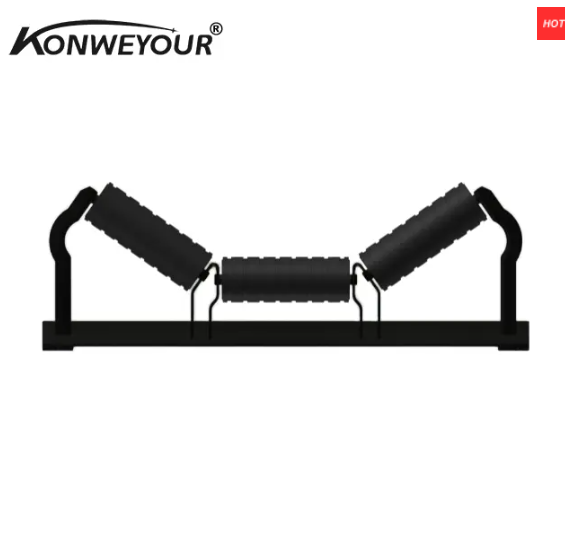

In contrast, a Roller Conveyor consists of a series of cylindrical rollers mounted within a frame. Products move over the rollers either by gravity, manual push, or powered rollers driven by motors. Roller conveyors are best suited for transporting rigid, flat-bottomed items like boxes, pallets, or containers. They provide greater flexibility for sorting, accumulation, and merging processes in assembly lines and distribution centers.

The key differences include the type of product they transport, their movement mechanisms, and their adaptability to different environments. Belt conveyors offer continuous, enclosed transport, reducing product damage and spillage. Roller conveyors provide easier access to products and are often more cost-effective for certain handling tasks.Choosing between the two depends on the nature of the product, handling requirements, space constraints, and operational needs. Both conveyor types contribute significantly to improving workflow efficiency and reducing manual labor.